Electrified Aircraft: What is it and why is it important?

What is driving the need for aircraft electrification?

Aerospace companies are currently faced with the challenge of designing aircraft to meet performance and efficiency needs. Needs that are predominately shaped by global governments as they work to reduce CO2 emissions and oil dependency. In order to do this, aerospace companies are dependent on developing alternative power sources – specifically hybrid electrification.

- What is hybrid electric aircraft? A hybrid electric aircraft is an aircraft with partially or fully electrified primary power systems. Primary power, generated by the jet engines, is what propels (thrust) the aircraft.

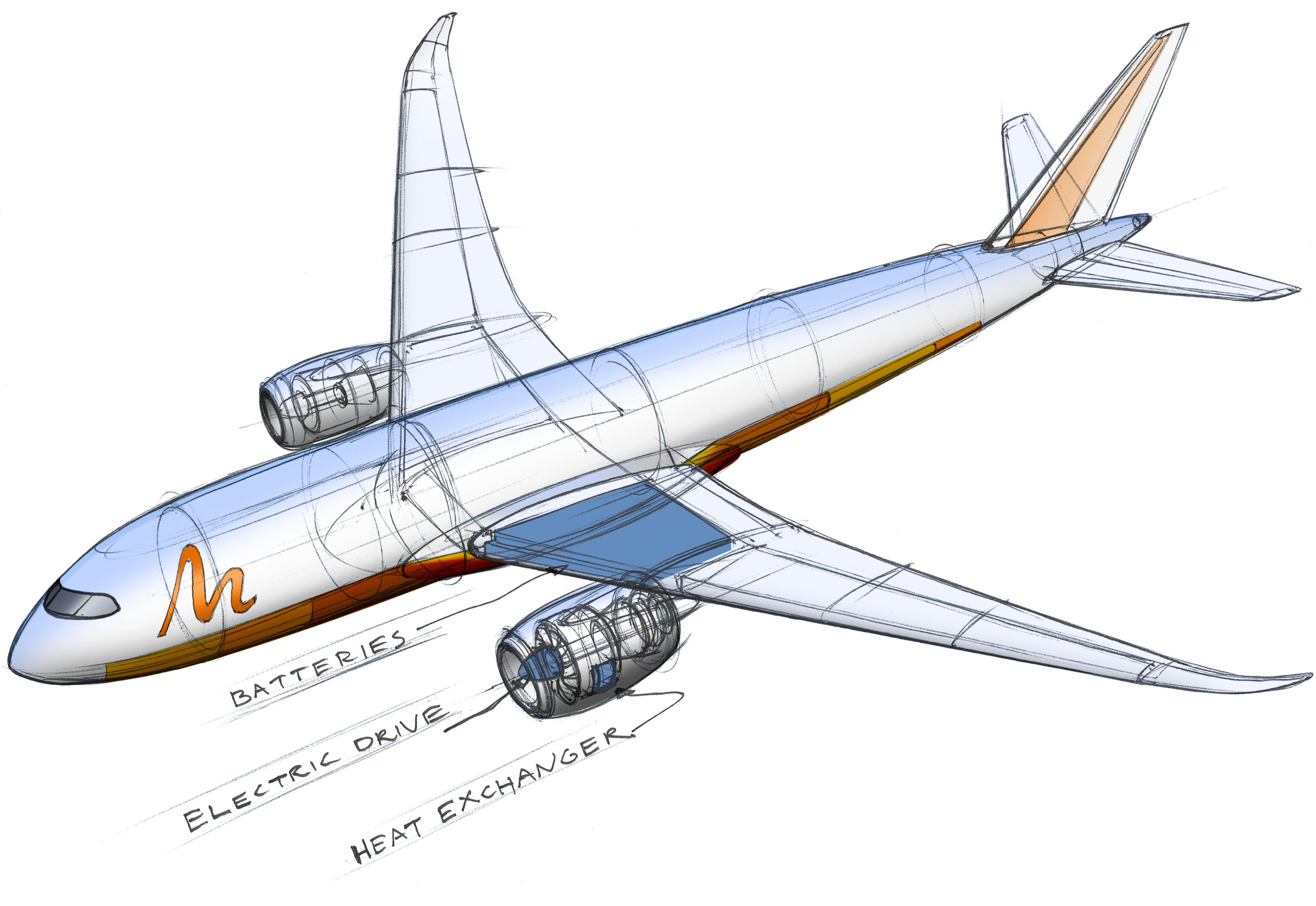

- How is power generated in hybrid electric aircraft? Simply, gas turbines on-board the aircraft generate electrical power, which is conducted through a power distribution sub-system to electric drives. These are integrated into distributed propulsion sub-systems, which propel the aircraft.

What are the challenges for achieving aircraft electrification?

The possibility of commercial aircraft electrification is appealing and offers many benefits like emission and noise reduction but also comes with a significant amount of challenges, including battery technology development and thermal management systems.

- Battery technology: For commercial aircraft, the energy storage density from batteries is simply too heavy. Jet fuel contains 30-60 times the net energy per mass of batteries. For this reason, fully electrified aircraft only work for aircraft with few passengers. With today’s batteries, a fully electrified large aircraft could only fly around 200 miles.

- Thermal management: Creating a practical cooling system that can be used will require a system that can reject anywhere from 50 to 800 kW of heat in flight. A cooling system is required for the integrated power module used for high-power electronics, batteries and electric drives. Materials will need to be developed for improved thermal performance, and a lightweight system developed for the electrical power system cooling. Superconductivity and supercooled electronics may be required to reduce the electrical resistance of the aircraft.

Does aircraft electrification have a future?

Modelon is proud to be leading the way in research. Working as a collaborative partner in the Turbo electRic Aircraft Design Environment (TRADE) project, funded by the Clean Sky 2 Joint Undertaking – under the European Union’s Horizon 2020 research and innovation program.

The TRADE project is a collaboration focused on using physics-based simulation to develop a system level model with deployment of different hybrid-electric architectures: parallel, series, turbo-electric in the propulsion system. Specifically, TRADE researchers will look at modeling a design in which electric drives will boost gas turbines that generate extra thrust for the aircraft; thus, handling power peaks that otherwise need to be covered by the gas turbine. To test the feasibility of such a design will require researchers to step away from conventional engineering methods, as these methods rely on statistical data and classic problem breakdowns.

The project consortium includes: Mälardalen University, Technische Universität Berlin, The University of Nottingham.

TRADE research results will be available in early 2020.