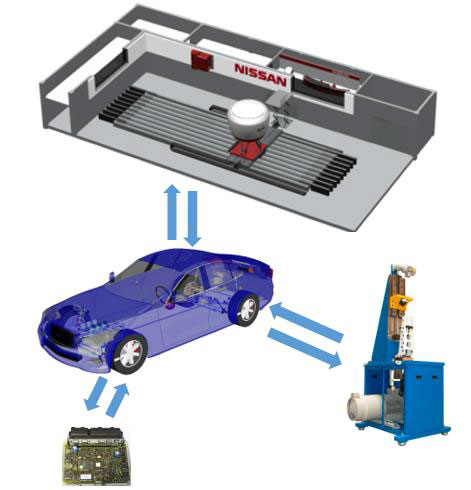

Virtual Vehicle Kinematics and Compliance Test Rig

SUNDSTRÖM, P., HENNINGSSON, M., AKUTAIN, X., HIRANO, Y., ET. AL:

MAY 23, 2016

Japanese Modelica Conference 2016, Tokyo, Japan

Introduction

Virtual representations that can predict a vehicle’s real life behavior have become more and more important in the development process. There are some well-known reasons for this, such as overcoming the cost, time, safety and repeatability issues with physical prototypes (Rauh, 2003).